Technology

CFS® solutions address new environmental issues in architecture, construction and civil engineering, public infrastructure and equipment (urban furniture), OEM manufacturers, architects, real estate and hospitality.

TechnoCarbon’s comprehensive skillset provide for adequate composite material solutions to be delivered to customers and prospects, according to their needs at the best quality/price ratio.

Multi-tasks

Thanks to its technology, TechnoCarbon offers products in Pierre-Carbone (CFS): semi-finished in the form of thin and thick sheets, walls, beams, building elements, pipes and other parts for equipment.

Functional

Pierre-Carbone (CFS) is perfectly adapted to the needs of the civil engineering, construction, energy, aerospace, defence and design sectors.

Since it does not use any rarefied natural resources such as fresh water or sand, it offers many economic, technical and environmental benefits.

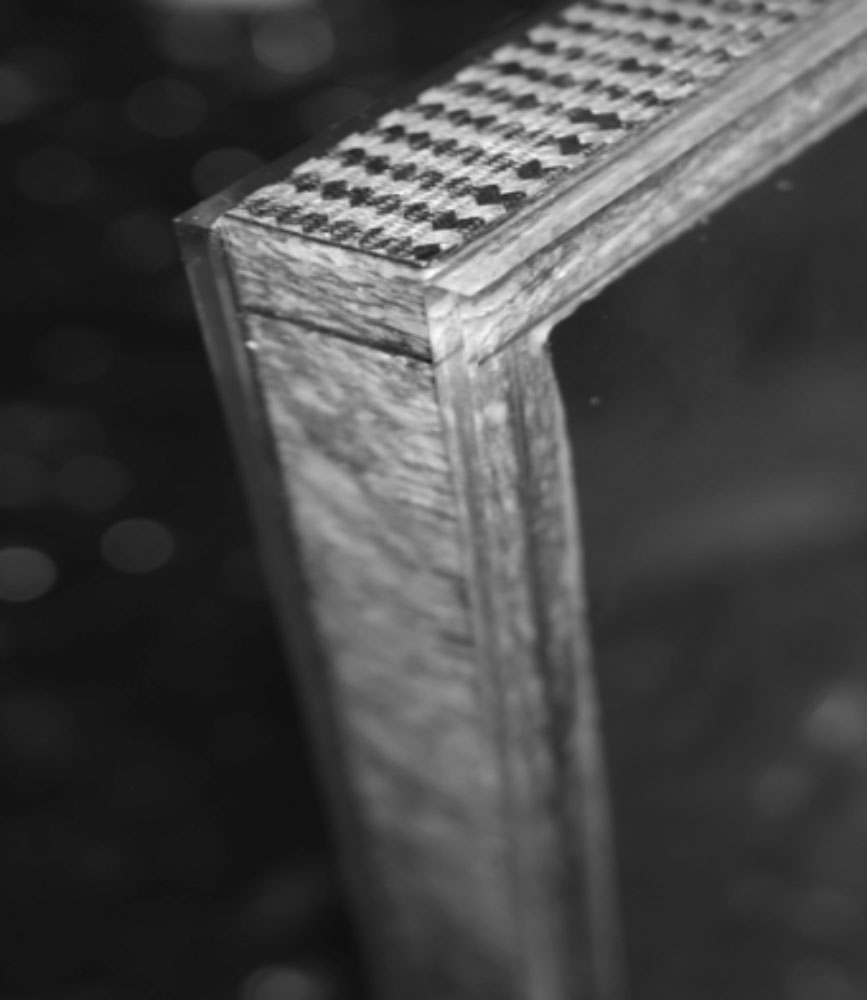

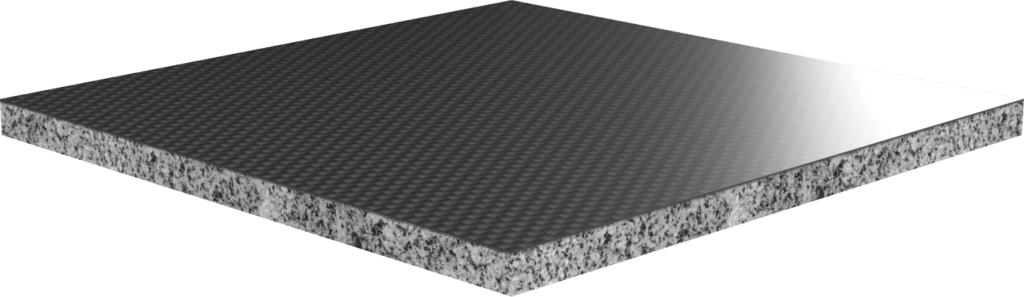

Composition

Pierre-Carbone (CFS) is a stone – carbon fibre layered composite material. It is cured at relatively low temperature compared to other materials such as metals or cement, thereby enabling substantial manufacturing energy savings. The stone can be replaced by other minerals (glass, ceramics, recycled materials) allowing, in the long term, to create new products that are more economical or even more sustainable.

It is a family of composite materials whose manufacture has a carbon footprint 90% lower than that of conventional materials.

Carbon fibre

Developed in the 1950s and 1960s in Japan and the United States, carbon fibre has extraordinary physical properties: light, resistant and rustproof.

Until recently, its high cost has limited its use to aerospace and military applications.

Combining this cutting-edge material with stone offers industrial companies product solutions tailored to the current environmental context and its impact on sectors that emit high levels of CO2.

The benefits of Pierre-Carbone

In production

= ultra-low GHG emissions

In use

Slow decay

Industrial process

Pierre-Carbone is made by assembling two types of high quality materials: carbon fiber and stone, which represent 99% of its composition.

Zero waste, CO2, fine particles, use of sand, economical use of fresh water.

Production

Intellectual property

TechnoCarbon is at the forefront of innovation and has protected its technologies and manufacturing secrets through multiple patents registered with EPO or INPI.

The Research & Development aspect being a cardinal value of the company, some of them are still kept secret.